MAIN FEATURES

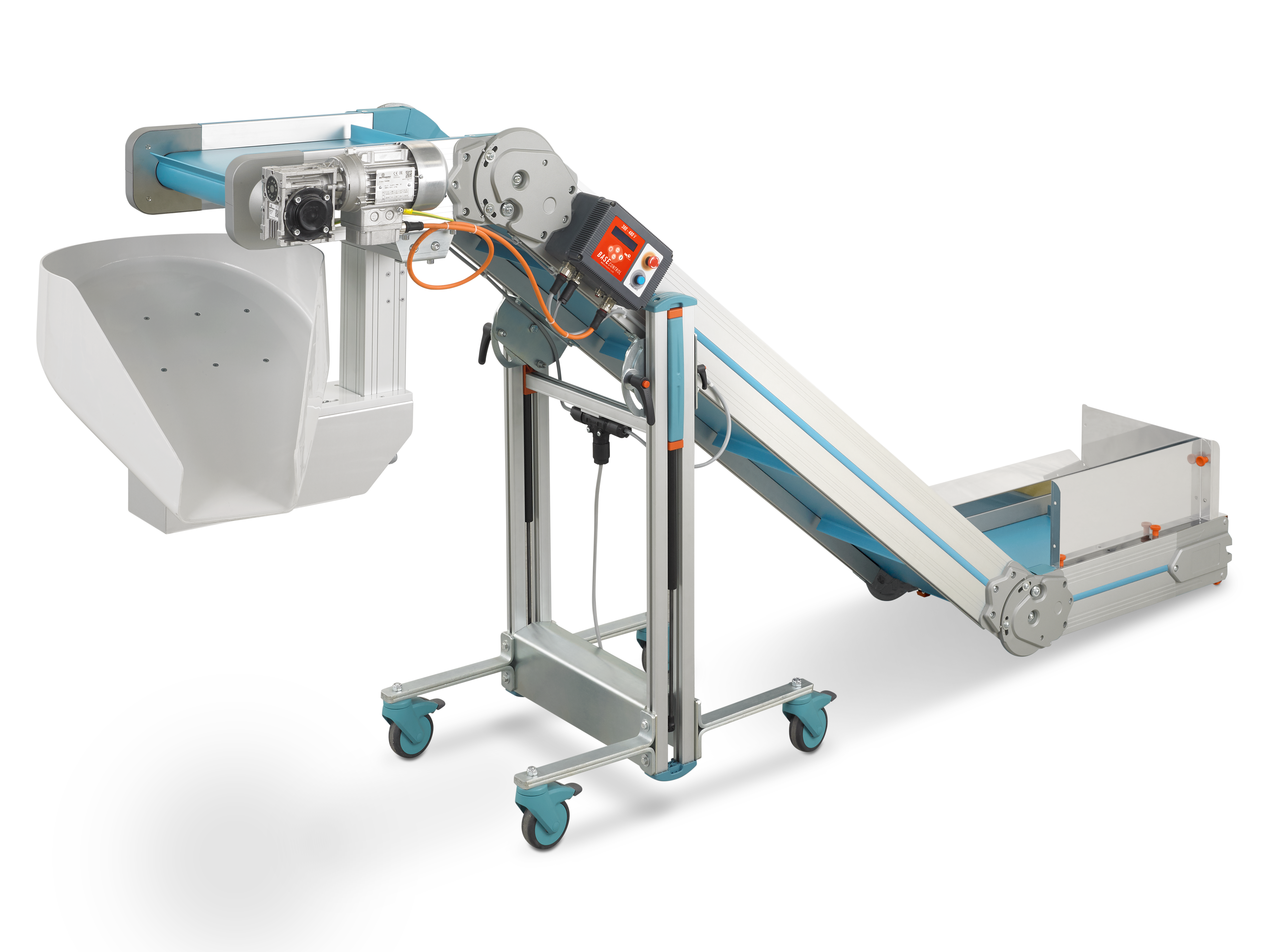

The N-Duck dispenser is specifically designed to be integrated onto MB conveyors and become part of it.

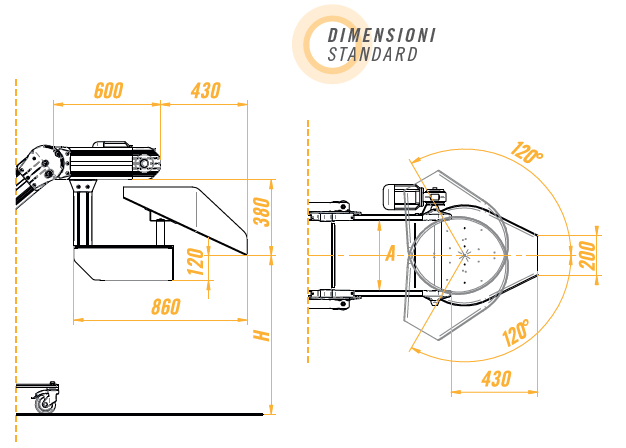

Its chute has a total rotation range of 240 ° (+/- 120 ° off the longitudinal axis of the conveyor), and within such range it is possible to set up to 9 unloading points, always at the same distance from each other, using the control panel installed on the conveyor.

Chute rotation speed: 240° in about 3 seconds

N-DUCK TRANSMISSION GROUP

-Voltage: 400V / 50 Hz

-With pre-wired connection kit

HOW IT WORKS

All N-Duck dispenser functions are managed, as a standard, by an MB Base Control panel, where it is possible to set:

– Number of unloading points

– Product filling modes:

• IMM cycle count

• Timed filling

ALARMS

If during chute rotation an obstacle is found, the device stops immediately and the word “ALARM DUCK” appears on the display. Once the obstacle is removed, pressing “RESET ALARM” button the filling is resumed from where it stopped

NOTES:

– If the desired unloading points cannot be reached with the standard version, it is possible to install MB Top Control panel: in this case, it becomes possible to manually set an unlimited number of unloading points.

-For technical reasons, N-Duck installation is only recommended within a specific dimension range ( i.e. A= min 240 mm, max 340 mm)