CAV

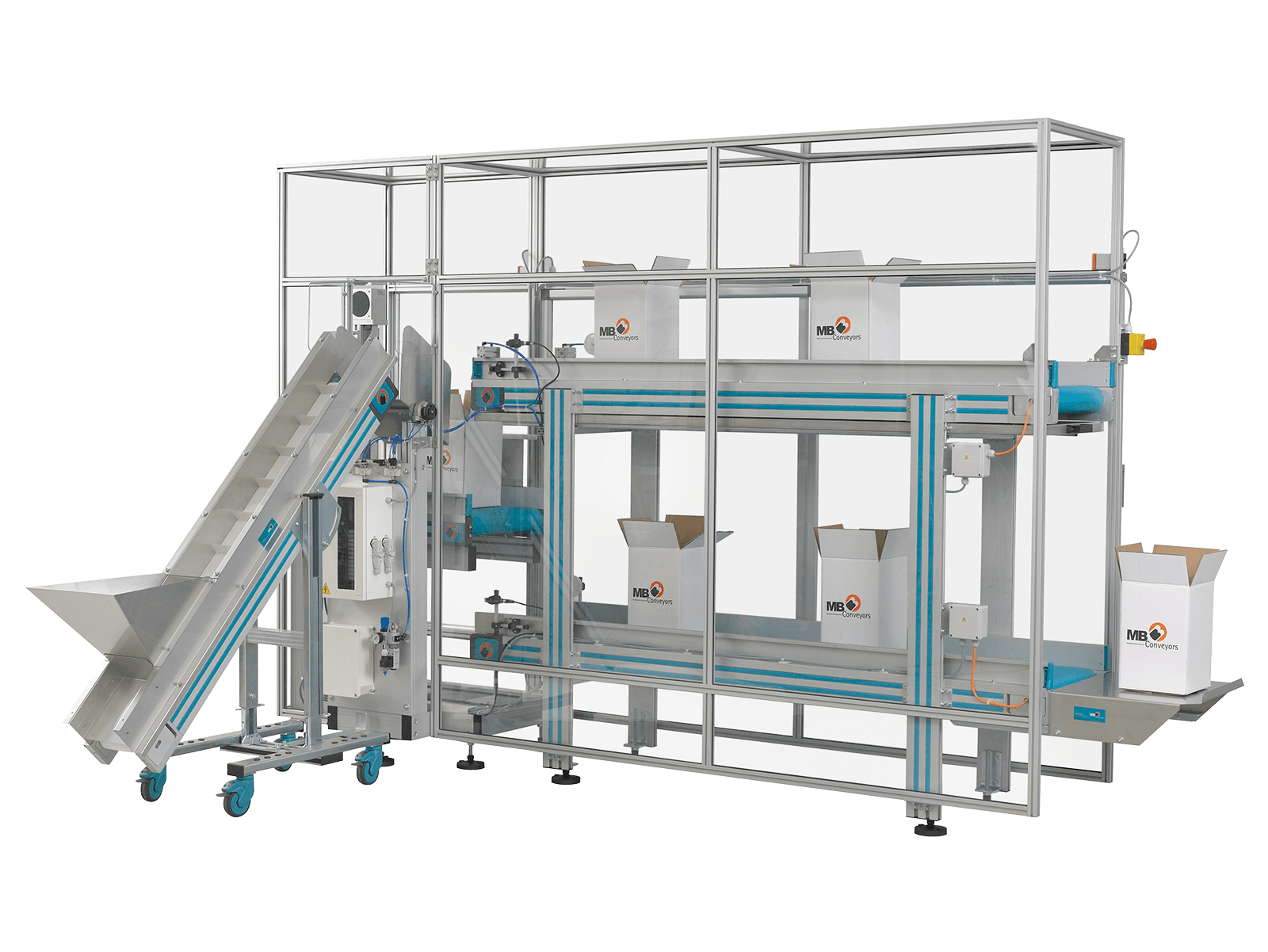

VERTICAL STORAGE SYSTEM

- CAV is an effective system for optimizing the storage process and increasing the working autonomy of the production unit, with excellent use of the available space

- The operating logic is automatically managed by a PLC control panel, and regulated by a photocells system for box presence detection

- Possible Options:

– Polycarbonate safety / dust protections

– shaking device placed under the box during the filling phase

– filling by weighing

Storage system

more than 8 boxes

STANDARD DIMENSIONAL FEATURES

STANDARD WORKING LOGIC

- Empty boxes are placed on the upper conveyor

- Box filling on upper conveyor or on elevator

- Filling by shot counting or weighing

- Full boxes are transferred onto to the lower level conveyor

CONFIGURATIONS

CAV - two-story vertical storage system

- Collects coffee capsules under the production unit and conveys them to the storage system, where they are stored after weighing

- Transport system complete with deionizing devices for the reduction of electrostatic charges

- Since the weighing takes place on the elevator, the carousel is equipped with a tilting chute, to enable quality check under the collection funnel

CAV - Shaking device detail

- Blue devices for blocking and shaking the box and photocells for detecting the correct box placement

- This shaking system allows a significant reduction in the number of boxes used for the storage of daily production, with savings on logistics costs too

CAV - double-lane vertical storage system

- The photo highlights a solution aimed at optimizing the use of available space, creating two lanes on the same conveyor for the empty boxes placement

- Special box stopping device and sophisticated photocells system to manage the autonomous operation of the carousel. A final idle roller conveyor facilitates the full boxes removal

CAV - two-story vertical storage system

- Collects coffee capsules under the production unit and conveys them to the storage system, where they are stored after weighing

- Transport system complete with deionizing devices for the reduction of electrostatic charges

- Since the weighing takes place on the elevator, the carousel is equipped with a tilting chute, to enable quality check under the collection funnel

CAV - Shaking device detail

- Blue devices for blocking and shaking the box and photocells for detecting the correct box placement

- This shaking system allows a significant reduction in the number of boxes used for the storage of daily production, with savings on logistics costs too

CAV - double-lane vertical storage system

- The photo highlights a solution aimed at optimizing the use of available space, creating two lanes on the same conveyor for the empty boxes placement

- Special box stopping device and sophisticated photocells system to manage the autonomous operation of the carousel. A final idle roller conveyor facilitates the full boxes removal

CAV - two-story vertical storage system

- Collects coffee capsules under the production unit and conveys them to the storage system, where they are stored after weighing

- Transport system complete with deionizing devices for the reduction of electrostatic charges

- Since the weighing takes place on the elevator, the carousel is equipped with a tilting chute, to enable quality check under the collection funnel

VIDEO

Category: Storage