CURVES

CURVED TRACK CONVEYORS

CONFIGURATIONS

Conveyor with 180° curved track and tapered rollers

- The curved-track conveyor allows the product to make a U-turn as it is conveyed

- The most important feature of the curved-track conveyor is the quality of the conveying action: the conveyor receives product at the entrance and delivers it at the exit in the identical position

- The tapered shape of the driving and driven rollers can be seen in the photo. The minimum and maximum diameters of the rollers depend on the width of the conveyor and the inner curve radius

Conveyor with 90° curved track and tapered rollers

- Minimum possible inner curve radius = 300 mm.

- Maximum possible working width of curved track = 2500 mm.

- There is a direct relation, equal to 1/2, between the minimum curve radius and its working width (for example with 300 mm inner curve radius (1), the maximum possible width will be 600 mm. (2))

90° curved-track conveyor with “thin” rollers

- 90° curved-track conveyor with 20-mm diameter driving and driven rollers

- This solution is useful when the diameter of the end rollers must be very small so as to facilitate product transfer from one conveyor to another.

- The products conveyed are usually very small.

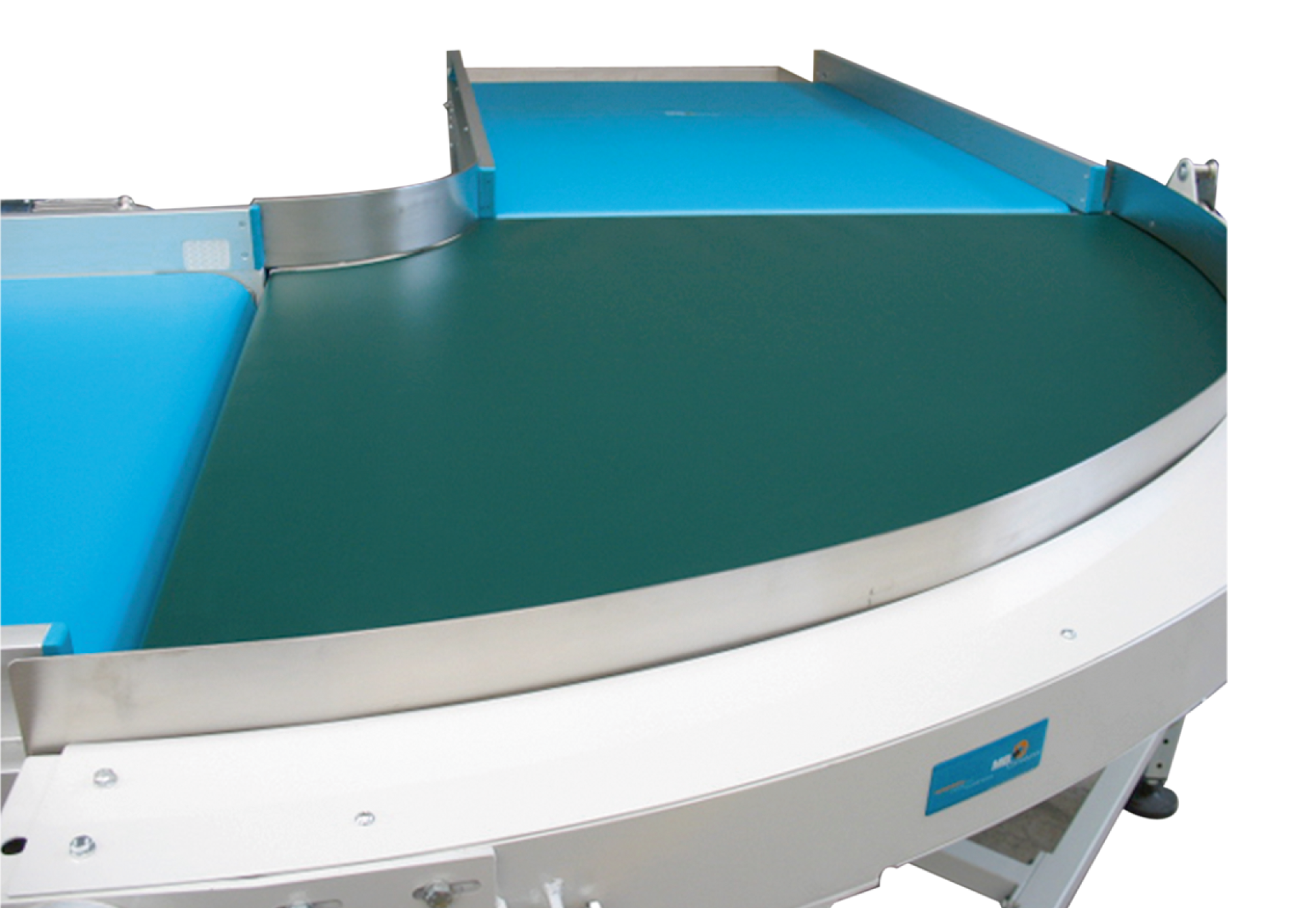

90° curved-track conveyor installed in a conveyor line

- The photo shows a 90° curved-track conveyor installed between the incoming and outgoing conveyors

- If a curved-track conveyor must be “inserted” into a conveyor line, it is important to know the exact shape of the products to be conveyed to prevent problems as they switch from one conveyor to another.

- The precision of the connection between flat sections and curved-track sections is evident in the photo

90° curved-track conveyor installed in a conveyor line

- Curved-track conveyor with Ø20 thin end rollers installed in a conveying line between two flat conveyors

- Note how the flat belts have special, thinner rollers to facilitate the products as they pass from one conveyor to the other. The h 40 mm side panels help to keep the products within the line

- 300 mm is the minimum inner radius for this type of curved track

Conveying line complete with 90° curved track

- The photo alongside illustrates an accumulation and conveying line for two plastic components as they leave two Robot-assisted moulding units for subsequent assembly together.

This implied that the two different components had to be conveyed along a route that carried them to a strategic assembly point

Raised conveying line complete with 90° curved track

- The photo alongside shows an accumulation line for plastic components leaving a Robot-assisted moulding unit to be subsequently conveyed to an assembly or sorting point while avoiding obstructions on the ground which could not be removed. The solution was to create an overhead line where the product was first raised, then lowered and also included a 90° variation of the conveyor track

Category: Conveying