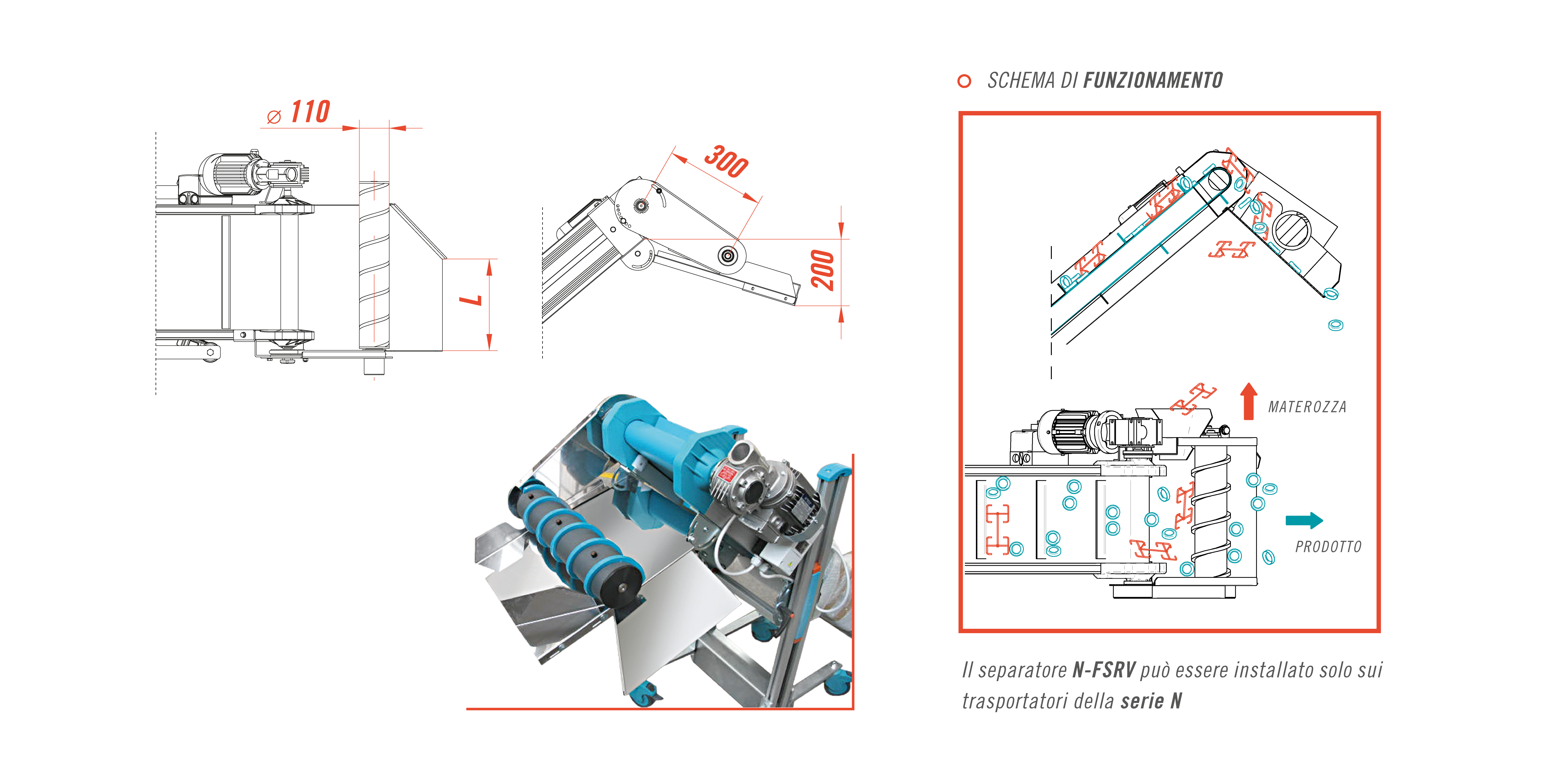

N-FSRV

SPIRAL SEPARATOR

- The spiral roller is driven by the gearmotor of the conveyor and drive is transmitted by means of a PU belt

- The distance between spiral roller and unloading chute can be adjusted to a recommended maximum 70 mm

- Speed of spiral roller: 14 rpm

- The spiral of the separator roller is made of 10×10 mm section PU profile

- The standard pitch of the spiral installed on the roller is 80 mm

- In view of the particular functional characteristics of this separator, MB recommends that a test be performed at the offer stage using samples of the products and sprues to be separated

STANDARD DIMENSIONAL FEATURES

CONFIGURATIONS

N-CPR WITH SEPARATOR N-FSRV AND BELT WITH ``BANDE BOARD`` IN THE FDA VERSION

- The solution in the photo alongside is widely used in moulding processes for the medical industry

- The lateral “Bande Board” prevents small products from getting caught between the belt and side panels

CP-PA WITH ROLLER SEPARATOR

- The solution in the photo alongside collects product at the side of a press through a chute and then separates it on a flat belt with a single roller separator installed at the end

- The unusual conformation is due to the need to reduce the amount of space taken up on the press

- The sprue is conveyed straight to the granulator, while the product is accumulated in dedicated containers

INCLINED NPA WITH SPIRAL SEPARATOR

- The photo alongside shows an FDA version of a mod. N-PA conveyor installed under a press in a cleanroom, complete with Polycarbonate covers and spiral separator for separating the sprues

INCLINED N-PA WITH ROLLER SEPARATOR

- The mod. N-PA incline conveyor in the photo alongside is designed for installation under a press

- Mod. N-PA is used when the space available under and on the press is very limited

- Conveyor complete with loading hopper and 10×6 mm feed dog to facilitate the conveying action

Category: Separation