PA TP

FLAT PLASTIC SLAT CONVEYOR

- Anodized ALU profile structure (thickness 15 Microns) Alloy 6060 with h 60 mm built-in side panels

- Standard MB plastic belt conveyor belt without slats. Slightly textured surface, h 16 mm side edges, complete with padlockable switch/motor protector + cable and plug

- The side edge does not open even when the belt is turning on the driving pinion

- Belt details:

– Belt in glass-fibre reinforced PA6

– Min and max temperature resistance of belt: from +1 to +130°C

- Speed: 6.5 m/min fixed

- Voltage: 400 V / 50 Hz

- Std installation: on left-hand side with drive and shaft-mounted flange

- Worm reduction gear with life-long lubrication

High temperatures

and electrostatic charges

STANDARD DIMENSIONAL FEATURES

CONFIGURATIONS

PLASTIC SLAT CONVEYOR LINE FOR INSTALLATION UNDER BLOWER-MOULDER

- This type of application is a very common solution for picking up blower-moulder waste and channelling it towards the granulator for recovery

- In this case, the choice of a plastic belt conveyor was dictated by the high temperature reached by the outlet product

PA TP WITH PERFORATED belt AND CENTRIFUGAL FAN

- Example of a flat perforated plastic belt with cooling system comprising a centrifugal fan and heat exchanger

- Thanks to its particular conformation, the perforated plastic belt allows air to circulate and is ideal for use in applications where cooling is required

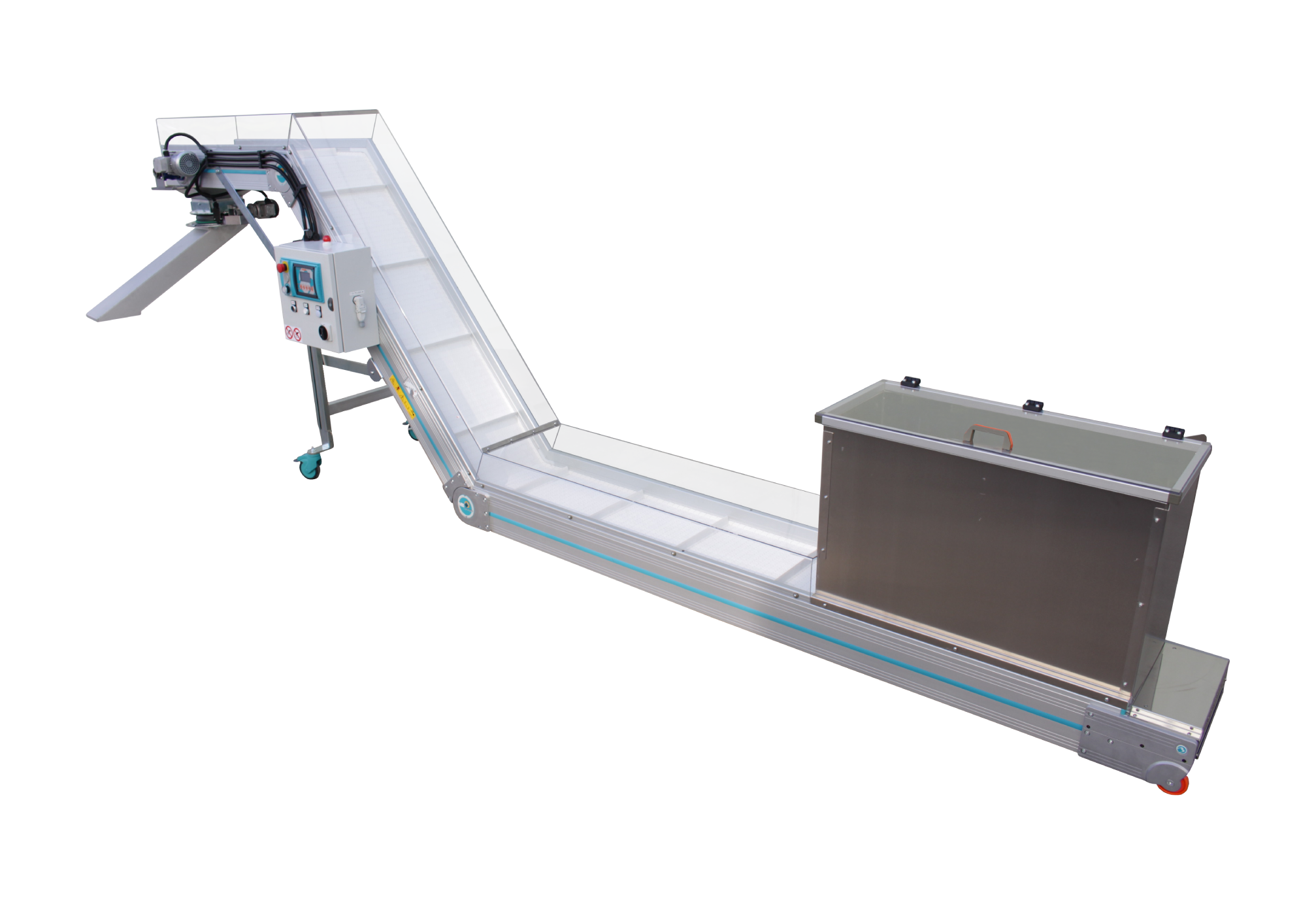

MB TPS WITH PLASTIC belt

- Example of an MB TPS model with plastic belt

- This model is typically used in assembly and packaging lines, for loading other machines or for vertical accumulation systems

EV WITH PLASTIC belt

- Example showing how versatile the plastic belt can be, since it can be used to make different types of conveyor, especially when high temperatures are involved or when sharp or pointed products must be conveyed

- In this case, the plastic belt elevator conveys metal parts inside a circular vibrator

T-CONVEYOR WITH PLASTIC belt

- The T-Conveyor conveying and accumulation system is widely used in the PET preform manufacturing industry

- Use of the plastic belt for this type of application is recommended when the preforms are very hot when they leave the press and especially when there are problems involving electrostatic discharge.

CPT TP WITH ROTATING CHUTE

- The photo alongside shows how plastic belt conveyors can also be fitted with a broad range of accessories to make them even more versatile: in this case, the mod. CPT conveyor has been equipped with a fully openable top hatch and rotating chute that unloads in 8 positions

CPT TP WITH SRS

- Plastic belt conveyors can also be fitted with sprue separators, another of the versatile ways in which they can be used

- In this example, a mod. CP conveyor with an MB plastic belt is equipped with an SR single-roller separator

CPT TP WITH CENTRAL PARTITION

- The photo alongside shows how a central partition can been applied to a plastic belt conveyor for the purpose of creating two separate lanes for the product and its sprue

- A chute with two outlets at the end of the inclined section allows the product to be transferred to a work table on the right, while the sprue is conveyed straight to a small granulator on the left

Category: Plastic belts